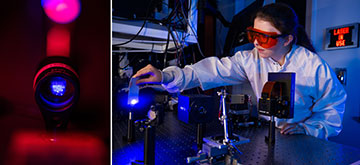

Elizabeth Blackert, who recently completed her doctorate at Rice University, led the development of a soft robotic arm that can perform complex tasks. [Image: Jeff Fitlow, Rice University]

The stereotypical robot consists of hard metal and plastic parts with a limited range of motion. Increasingly, researchers are designing robots made of softer materials capable of handling delicate tasks with wide-ranging, easily adaptable movements—and light can be an important component of such a system.

Researchers in the United States have now developed a soft robotic arm that changes shape under the influence of laser light (Adv. Intell. Syst., doi:10.1002/aisy.202500045 ). The team built the device with a photochromic polymer that shrinks when exposed to certain wavelengths and relaxes in the dark and leveraged a neural network to deliver a pattern of laser signals that remotely controls the arm.

A light-sensitive polymer

Azobenzene is the umbrella term for a class of organic polymers that undergo photoisomerization—the molecules change shape when exposed to light in the ultraviolet and blue parts of the spectrum. Recently, scientists have explored azobenzene liquid crystal polymer networks, which contain long molecules that line up in different ways. Light exposure makes these polymers deform themselves in a rapid, reversible and repeatable manner.

Many scientists have already tried building simple grippers and other devices from azobenzene networks, but their efforts usually required manual control of the activating light or simple light pulses. Researchers from several departments at Rice University harnessed machine learning to drive a spatial light modulator (SLM) that produced precise patterns of light to control the soft arm.

Bending the arm with light

For their proof-of-concept experiments, the Rice scientists selected an azobenzene liquid crystal that responds to blue light instead of UV light, since the latter could harm living cells in future medical applications.

Researchers from several departments at Rice University harnessed machine learning to drive a spatial light modulator (SLM) that produced precise patterns of light to control the soft arm.

The group fabricated a simple arm out of the photosensitive material, then set it between two 450-nm continuous-wave lasers pointing in opposite directions. Lenses connected to the SLM either directed portions of the laser beam onto the soft arm or deflected the light away from it.

After bending the arm manually and photographing the results, the researchers used the images to train a convolutional neural network to direct the motion of the arm. The resulting movements were precise and quick enough that the arm could “kick” a small ball over a flat surface. “This was the first demonstration of real-time, reconfigurable, automated control over a light-responsive material for a soft robotic arm,” said study author Elizabeth Blackert.

In future work, the team could add a second camera to improve the 3D precision of the arm’s movements. Other potential improvements include using more complex machine-learning models and finding a polymer network that responds to infrared light.

“This is a step toward having safer, more capable robotics for various applications ranging from implantable biomedical devices to industrial robots that handle soft goods,” Blackert said.