Feature

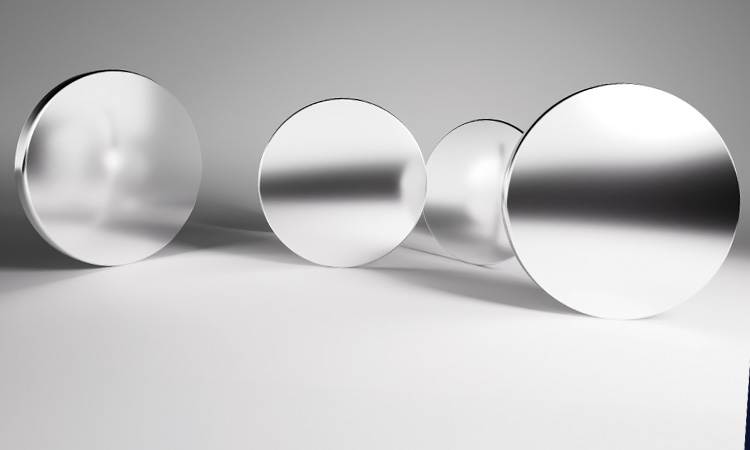

Unlocking the Secrets of Replicated Mirrors

Replication offers a cost-effective method to produce complex optical geometries on diverse substrates complementing traditional “grind and shine” techniques.

[Getty Images]

[Getty Images]

High-performance mirrors sit at the heart of modern optical systems, and system capability often scales with aperture size and surface precision. Conventional routes to optical component fabrication, such as precision grinding and polishing of glass or glass-ceramics to tight figure tolerances (e.g., fractional-wavelength surface figure error (SFE) at 632.8 nm) deliver excellent optics. However, lead time, cost and component mass increase steeply with aperture and geometric complexity. Programs that push for larger clear apertures, tighter tolerances or non-rotationally symmetric geometries face schedules measured in months to years, risk to yield, and structures that can be prohibitively heavy for space or airborne platforms.

…Log in or become a member to view the full text of this article.

This article may be available for purchase via the search at Optica Publishing Group.

Optica Members get the full text of Optics & Photonics News, plus a variety of other member benefits.