Julia Somerdin

The July/August 2025 issue of Optics & Photonics News featured the magazine’s biennial feature spotlighting 10 Entrepreneurs to Watch. Here, we offer an interview with one of those entrepreneurs, Julia Somerdin, chief executive officer (CEO) of Labby. Labby integrates optical-based sensing technology directly into the milking equipment at dairy farms to offer real-time data on herd health and milk quality.

Can you summarize what Labby is doing and your future directions?

Labby is transforming the dairy industry by bringing real-time milk testing to the farm. Our optical sensing technology integrates directly into milking equipment to give farmers instant, actionable insights into milk quality and cow health.

Traditionally, milk testing is slow and infrequent—often once a month, which leaves farmers flying blind. We’re changing that. By enabling continuous, automated milk testing, we help farmers make data-driven decisions faster, leading to better herd health, operational efficiency and food safety across the dairy supply chain.

We see ourselves as a platform for “optical intelligence in milk.” Just as electronic medical records have revolutionized human health, we believe precision data will do the same for animal health—especially in light of zoonotic disease risks like COVID-19 and avian flu. We’re building the infrastructure to make livestock data as ubiquitous and impactful as patient data.

What inspired you and your cofounder Anshuman Das to develop Labby?

It was part technical curiosity, part personal passion and part unexpected inspiration from the field. I come from a deep tech background in IoT (Internet of Things) connectivity network and electronics. I spent over 15 years in the enterprise tech space—building platforms that solve complex, industry-wide problems. I’ve always sought out innovations that create real impact.

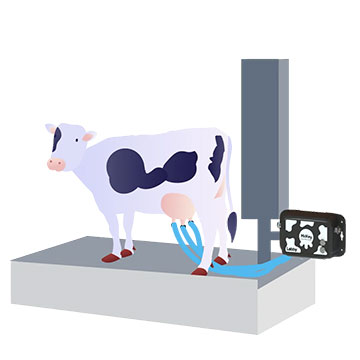

Labby's MilKey technology, which can test raw milk on a dairy farm in real time. [Image: Courtesy of Labby]

While studying system design and management at the Massachusetts Institute of Technology, USA, (MIT), I was invited to present at the 2018 MIT Nano Summit. That’s when Das and I showcased our optical sensing technology. We had early interest from chemical and medical companies, but to my surprise, dairy professionals in the audience asked me, “Can your technology be used on dairy farms to test raw milk?” That was a turning point.

I grew up spending summers on my grandfather’s farm—so agriculture already had a place in my heart. But I didn’t know anything about dairy. So we spent months talking to farmers, walking barns and understanding workflows. That’s when we learned how outdated milk testing really is. Samples are collected manually, often by a technician driving 100 miles a day. It’s costly and infrequent. And the Dairy Farmers of America (DFA) invited us into their innovation cohort, which gave us inside access to the real problems dairy professionals were facing. That’s when we knew we had something worth solving.

Why did you decide to return for your master's at MIT?

It was a defining moment. I had 15 years of corporate experience and strong technical skills, but I wanted to pivot toward entrepreneurship, toward building something that mattered. MIT doesn’t allow part-time study, and I had a full-time job and a young son. It was a demanding year. But I knew I needed a different environment to stretch beyond corporate norms.

MilKey is integrated directly into the cow-milking system on the farm. [Image: Courtesy of Labby]

I also volunteered as a sponsorship chair for an MIT startup club, raising funds for demo day. That experience taught me the startup ecosystem—from fundraising mechanics to community building. That’s when I realized: I not only had the technical chops, but the hustle and resilience it takes to build a company. Labby was born from that realization.

What is the benefit of Labby’s optical-based technology, compared to existing lab-based methods?

The core problem is lack of data. Farmers are losing money every day because they can’t detect issues soon enough. Most testing relies on lab-based methods—chemical staining and flow cytometry—which are expensive, labor-intensive and slow. That’s why many farms only test once a month. But cows get sick more often than that, and untreated milk ends up in the bulk tank, affecting the entire supply chain.

With our system, the testing happens in real-time, right at the point of milking. That means farmers can identify issues immediately and divert milk from sick cows before it contaminates the tank. This is critical for food safety, profitability and sustainability. Our technology is cost-effective and scalable, and it works across different farm sizes and setups. And we’re not just delivering hardware—we’re providing a continuous stream of data that allows farms to make informed, fast decisions. That’s our real value.

I had 15 years of corporate experience and strong technical skills, but I wanted to pivot toward entrepreneurship, toward building something that mattered.

What challenges have you experienced bringing your products to market and getting them implemented?

Hardware is tough—and our hardware is embedded in one of the most unpredictable environments you can imagine: the dairy parlor. You’re working with massive animals, highly complex milking systems and daily washdowns. It’s not just about building a sensor—it’s about building a rugged, reliable system that can survive in the field. And it has to integrate seamlessly into existing milking equipment, which varies by farm. That complexity can’t be underestimated. We had to learn the dairy system inside and out. We became experts not just in milk chemistry, but in milk flow and sampling design, cleaning protocols, and parlor workflows. That hard-earned knowledge is now our moat. It’s why partners trust us—and why our system actually works in the field, not just in the lab.

How has participating in accelerators like Techstars and Luminate helped Labby’s development and success?

Each played a critical role at a different stage of our journey. Techstars gave us structure and discipline—something every early-stage founder needs. It taught us how to prioritize, build KPIs and stay focused.

Grow-NY was a game-changer. We won $250,000 in 2022, which gave us the capital and confidence to keep going. It also connected us to the New York dairy ecosystem.

Luminate brought us to Rochester—a hub for optics and precision manufacturing. That’s where we found the right vendors, talent and partners to go from prototype to product. Today we have a growing team in Rochester, and we’re scaling commercial installs across North America.

Can you talk about Labby’s sustainability efforts?

The dairy industry is under pressure to cut carbon emissions. But you can’t manage what you can’t measure. With Labby’s data, we can correlate feed inputs, digestion efficiency, and milk output on a cow-by-cow basis. That opens the door to precision feed strategies that reduce emissions while boosting yield. Eventually, this could lead to farm-level carbon scores and even carbon credits. Imagine a world where every gallon of milk has a sustainability label—certified by real-time data. That’s where we’re headed. We want to empower consumers with transparency and reward farms that are doing it right. Labby’s role is to build the data layer that makes it all possible.

With our data you can track when the feed is going to the cow and getting digested. And how the animal processes the feed directly reflects in the feed formula and in the milk components. So by combining all of the data we can gather, we can really provide farm-by-farm, cow-by-cow, carbon credit indexes. And that can build data-driven incentives by showing when a farm is a greener farm, so that they can receive a carbon credit.

Ultimately, our data really can help track the carbon credit, resulting in a reduction of emission for the dairy industry that in return will build more trust with consumers. Consumers want to know where their milk and cheese is coming from.

One day, we would love to be able to provide a certification to green farms. With the carbon credit index, we can really say the farm is certified by lab technology. That's how we can insert ourselves into the food supply chain. It's a long road to go, but if we can offer a certificate standard it can help the consumer make informed decisions when they’re shopping for dairy products and help to incentivize farmers even more.