![]()

Kaylee Hakkel. [Image: MantiSpectra]

The July/August 2025 issue of Optics & Photonics News featured the magazine’s biennial feature spotlighting 10 Entrepreneurs to Watch. Here, we offer an interview with one of those entrepreneurs, Kaylee Hakkel, chief operating officer (COO) of MantiSpectra. MantiSpectra develops miniaturized, integrated spectral sensors for use in the field.

What’s the “elevator pitch” for the company?

At MantiSpectra, we have developed a spectral sensor that we can use to sense the world around us, to determine the properties of a material using just light. We can, for example, determine the properties of food—how much sugar there is in a certain fruit. Or we can use it in bigger food factories and other types of factories for process control on a larger scale. But there are also a lot of applications in the health sector. For example, we have smart watches now, so you can measure biomarkers in your skin, moisture levels, also PPG. These kinds of things are becoming more important. So those are all applications for our chip.

Can you tell us about your road to MantiSpectra?

I decided to study applied physics at the University of Eindhoven, so that’s how it all started. At that point, I have to say that photonics was not so popular just yet. But I joined a photonics group for my bachelor’s end project, and that was the first time I got in touch with photonic sensors. Then I came back to that same group for my master’s graduation project and later, my Ph.D. During my Ph.D., we tried to focus on spectral sensors. We all know that there are big spectrometers in a lab and that they are very expensive, but we want to have devices that are small and portable and mass producible, because we want to have this beautiful technology available for everyone. We don’t want this to be technology that only people in a lab can use.

When I joined the group, the team had already done a lot of research and developed a microspectrometer that was working really well with very high accuracy. But it was not something that could be used in the real world; it couldn’t check your vegetables or be integrated into a process line. So when I started my Ph.D. project, the goal was really to come up with a real-world, mass-producible solution. I started working on that with my colleague, Maurangelo Petruzzella. He was a postdoc then, and now he’s CEO of MantiSpectra.

To be honest, when I was studying, I didn’t think, “oh, I’m going to start my own company.” At the time, I think there was also less attention and promotion in Europe for starting companies. Toward the end of my Ph.D., there was more attention on entrepreneurship and more support from universities. But although I didn’t think of it initially, when you have a product like a sensor that is patented, of course it makes sense to try to bring it into the market.

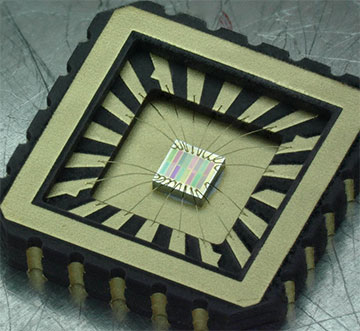

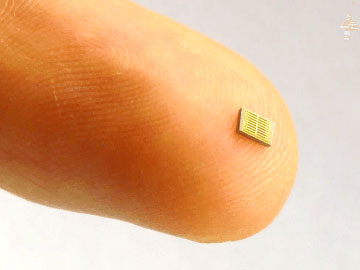

ChipSense. [Image: MantiSpectra]

My colleagues started the company as I was finishing my degree, so for me, the logical step was to join the company directly after I finished, and join the journey of taking a product developed in the lab out into the real world.

What is your role as COO?

The role of a COO depends on the phase you’re in as a company. We came from a university, where you’re working on deep tech research, and now we’re bringing it into the market. So of course, I’m responsible for the daily operations, meaning that everything needs to run and that we need to deliver to our customers.

But one of the most important things now is focusing on setting up a supply chain, because we developed the whole production process. Our current goal is to produce chips in very high volumes because we are in the consumer sector, and we have customers that need chips in big numbers. So I’m really focusing on that. And I think it’s very valuable that I have also the technology background there, so I understand how we can transfer the process to other companies for production.

What are some of the advantages of the ChipSense product?

First of all, we have a monolithic approach. Some other companies make a separate detector and a separate filter element, and then later they need to combine it into a system. So that’s one option. But we really have it integrated. And in addition to that, we don’t have any moving elements, so that means we’re also way less sensitive to shock compared with other solutions. You can bring it out, and it’s okay if you move it around. Otherwise, if you have, for example, like a membrane, a MEMS device, it’s going to be quite tricky to move.

And because we use wafer-scale production, we can really scale up, and we can control the process very well. And I think that is what is needed in order to get into the actual market. You can make a sensor, and you can publish a nice paper about it, but if it’s not ready for the real world, then you’re not going to make it. So I think that’s what we have with our technology—it’s actually ready for that.

How do you make the leap to a consumer-ready product?

Since we started product development on the chip level, we tested some applications ourselves to see if it was working. But I think the next step is really talking to your customers, because if you don’t know what they want, you can’t make it for them. And our end goal is really to sell the chip, since that’s our core product. But to actually have a customer, you can’t just give them a photonics chip—no one knows what to do with that. So we also developed the whole system around it.

We have the development kit, so it has light sources and electronics integrated, and it’s a kind of plug-and-play solution to get used to the technology, and then you can start to make models. It’s not just a chip; you also need to make the prediction models behind it. This way, we can educate our customers while they get used to the technology, and then afterward they’re ready for just buying the chips.

Some of the MantiSpectra team. [Image: MantiSpectra]

I think that’s also important because we are the experts on making our chips, but we are not the experts on the end product. We don’t know how the consistency of certain foods are built up, and what you need to measure in order to get good feedback. We are not the experts on all the biomarkers that are in your skin, but we can provide the technology for you to measure it.

Are there applications that you have found particularly interesting or exciting?

In general, we have two main focus areas. The first one is process control. Our technology really helps with control of food processing because currently they have to take a sample, go to an external lab and do chemical testing. This takes a long time and creates waste. With our product, instead you provide real-time feedback to make a system smarter. So I think that is really nice.

On the other hand, health and fitness applications are really booming, and everything is becoming smarter. We all have smart watches, and also in your house, even dishwashers and other appliances are becoming smart. We see traction in both fields, and we can serve them with one single chip,

Can you talk about where the company stands in terms of business indicators?

We’re really in the scaling-up phase. We have several customers that have gone through the first stage where they decided to use our technology, and now they want to have bigger volumes. So that creates a need for us to produce these bigger volumes, and we’re in this phase now of scaling up together with our customers. And of course, the funding comes along.

It’s really the supply chain that is becoming crucial, because we are scaling up, not only as a company in that we are becoming more professional, but we’re also scaling up in the number of products that we can deliver. And I think that is the crucial point, because by doing that you of course, also scale up the volumes that you’re selling. A lot of people can make one thing, sometimes, that is perfect. But doing it again and again and again? That’s the trick. Getting to that stage where your product is mass-producible is an important milestone for every company that’s growing.

Before the end of this year, our ability to produce at these higher volumes should be in place. I think that we are on a good track to get there. We can already can deliver products, but in order to go to these bigger volumes, we need that.

What do you think are the biggest differences between academia and industry?

It’s a completely different world. I think if you’re still a researcher, you want to always get the best-of-the-best result. But is that really what you need most of time? The answer is clearly no—you need to listen to customers about what they need. Maybe they want something that’s cheaper, even though it’s not the perfect performance, and then that’s what you need to produce.

ChipSense. [Image: MantiSpectra]

I think you need to focus on making something that’s actually useful instead of always making the very best thing. It’s a completely different perspective, and every day I’m still learning something new.

What is your longer-term vision for this technology?

We started with a certain chip design, which is our standard design. But to go into the full consumer market at some point, we need to go even to smaller chips. So we have a well-established product now with ChipSense, but there will be newer versions, and R&D will be based on trying to go smaller. And I think we first need to have a full established standard product in big volumes, in order to go there as well with a miniaturized version.

What market sizes are you looking at?

That depends on the sector. The volumes are lower in the process-control sector, but process control is really important, and there you become more into the Internet of Things, with all sensors connected to each other. But that’s a different size than when you go really into to the consumer sector. The consumer sector is big, there you go really into the millions.

There’s a lot of attention now on photonic integrated circuits, but what we have is a bit of an odd one because we have a sensor that is also working in free space from the top. We don’t need difficult waveguide couplings and all these kind of things. And I think that also allows us to actually enter these markets.

Do you have any advice for someone who might be trying to decide which path they want to take?

Try it out. We have a lot of interns, for example, who come and work with us during their studies. They join us to learn and to see how it is. I think until you’re in there working for a company, you don’t realize what the differences are. There are a lot of opportunities to try out different roles nowadays.

Also, I think it’s always nice to bring a technology from a lab into the real world, and to see it used for actual big applications. And I think that is a dream—if you can follow it, everyone should. Although of course you can do amazing research on something that is never going to be used in these big volumes, but still has a huge impact on science. So it really depends on what kind of research you’re doing.