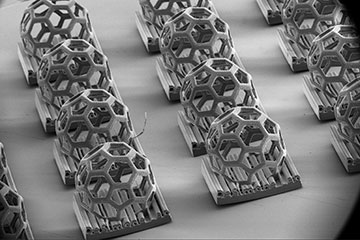

Researchers have made a variety of complex non-moldable shapes with micrometer-scale features, such as these buckyballs, using a new roll-to-roll 3D-printing technique. [Image: DeSimone Research Group, SEM courtesy of Stanford Nano Shared Facilities]

Scientists in the United States have demonstrated a new 3D-printing technique to rapidly fabricate complex, microscopic particles suitable for numerous biomedical and industrial applications (Nature, doi: 10.1038/s41586-024-07061-4). Combining light-induced polymerization and roll-to-roll technology, the method can generate up to a million particles per day with micrometer-scale resolution.

Producing microparticles

Particles with dimensions ranging from hundreds of micrometers down to nanometers find use in a variety of applications, from drug delivery and microfluidic systems to microelectronics and energy storage. These geometric specks of dust can either be made using bottom-up techniques such as grinding and milling or self-assembly, or else with top-down methods such as molding or lithography. But both broad approaches have their limitations―the former is quick but imprecise, while the latter yields only two-dimensional or simple three-dimensional particles.

In 2015, Joseph DeSimone and colleagues at Stanford University demonstrated an alternative technique known as continuous liquid interface production (CLIP) that involves using a computer model of a 3D structure divided into many horizontal slices. Those slices are used to create masks that pattern ultraviolet light shone from below into a vat of light-sensitive resin. The areas of the resin exposed to light transform into a rigid polymer structure. When the structure is gradually raised out of the vat, the end result is a solid version of the 3D model.

A technique improved

The researchers have now updated this technique to make it both faster and higher resolution. Rather than raising the evolving structure using a fixed device that is loaded and unloaded manually, the microparticles are instead built up on an aluminum-coated plastic film that is loaded from a roller, placed into position above the vat and then moved on. The section of the film with the newly minted particles―which typically number several hundred―is then passed through a cleaning stage and loaded onto another roller at the far end. At the same time, the adjacent strip of film is used to make the next batch of particles, which in turn is cleaned and loaded onto the second roller.

DeSimone and colleagues demonstrated their new “r2rCLIP” technique by fabricating a range of differently shaped particles, including both those that can be made by molding techniques and those that cannot (such as hollow tetrahedrons). They found that they could produce 30,000 particles in a little under an hour, implying a daily rate of about 1 million. Furthermore, they were able to change the features at will, while achieving sizes as small as just a few micrometers.

They found that they could produce 30,000 particles in a little under an hour, implying a daily rate of about 1 million.

Many materials

The researchers fabricated their particles using several different materials. One of these was a pre-ceramic mix, which after being heated to very high temperatures produced 100-µm-long ceramic microparticles. They say that such micrometer-scale ceramic geometries could have applications in micro-electromechanical systems or as waveguides.

They also showed that they could make 400-µm-wide cubes of hydrogel, which they filled manually with a suitable liquid and then topped off with another layer of hydrogel. The team said that these particles could be used to deliver drugs, with the pharmaceutical filled in such a way as to be released either gradually or all at once.

In a commentary piece to accompany the paper in Nature, Christoph Spiegel and Eva Blasco at Heidelberg University, Germany, say that a big plus of the new technique is the ability to fabricate a wide range of precision, uniform particles. “These features make the authors’ approach well suited to therapies that require specific particles to distribute drugs through different means; for example, by injection or inhalation,” they write.