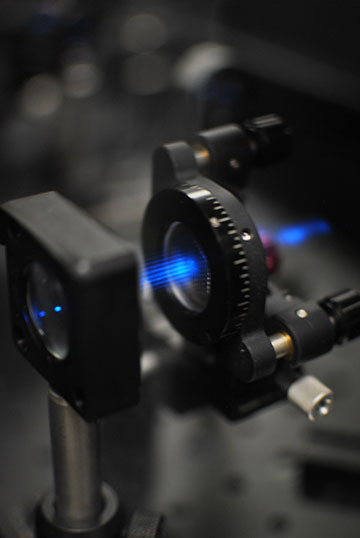

An inexpensive fabrication method exploits 3D printing and silicone molding to create a lenslet array that enables a multifocal structured illumination microscope to achieve super-resolution imaging [Image: Ralph Bauer, University of Strathclyde]

Researchers at the University of Strathclyde, UK, have shown that consumer-grade 3D printers and low-cost materials can be used to make complex optical components for super-resolution microscopy (Biomed. Opt. Express, doi: 10.1364/BOE.583760). With each lens costing less than US$1 to produce, the method offers an accessible route to creating customized optical elements that could unlock new innovations in imaging tools and techniques.

3D printing complex lenses

The Strathclyde team has previously shown that 3D printing can be used to fabricate optical lenses for standard biological microscopes. The shape of the optic is formed by building up thin layers of a clear resin, and then more of the resin is spin-coated onto the surface to smooth over the layers and improve the clarity and transparency of the lens. This versatile approach makes it easy to create bespoke optical designs while also yielding surface shapes that are smooth enough to compete with normal glass lenses.

Measurements show that this two-stage process produces lenslets with the same surface quality as commercial arrays, yielding smooth curved shapes that are comparable to ideal spherical surfaces.

In this new work, the researchers adapted their approach to produce lenses for a multifocal structured illumination microscope (mSIM), a design that beats the diffraction limit by exploiting patterned light to capture and combine multiple images with different focal points. To create the high-quality optics required for this super-resolution technique, the researchers needed to eliminate the scattering that can occur when a laser is focused through a printed lens.

Such unwanted scattering is caused by the individual voxels in the printed layers acting like a diffraction grating, a problem that the researchers overcame by adding a second stage to the fabrication method. First, they designed and printed a hexagonal array of millimeter-sized lenses to produce the multiple illumination points needed for the technique. From this printed optical element they created a silicone mold, which was then filled with a clear resin that hardens into a smooth and homogenous structure when exposed to ultraviolet light.

High-quality lenslets

Measurements show that this two-stage process produces lenslets with the same surface quality as commercial arrays, yielding smooth curved shapes that are comparable to ideal spherical surfaces. When the printed array was fitted to an mSIM built by the team, microtubules in a cell’s cytoskeleton could be imaged with a resolution of around 150 nm. That performance matched the level of detail achieved by two commercial glass arrays, one of which was a high-end version that had been fabricated using lithography.

The researchers believe that the extra design freedom offered by 3D printing could now inspire a variety of novel imaging scenarios. “Our new approach could empower scientists and companies to access tools previously locked behind specialist technology,” said lead author Jay Christopher. “Using budget-friendly 3D printers and materials, they could manufacture their own components to solve problems and generate unique solutions for research and product development.”