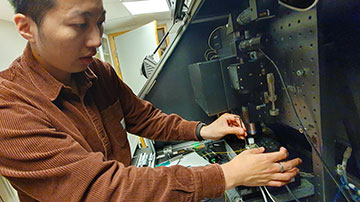

Lee-Lun Lai demonstrates the setup to print silica glass microstructures on an optical fiber. [Image: David Callahan]

Researchers in Sweden have invented two methods for fabricating inorganic glass structures on the tips of optical fibers―platforms roughly the width of a human hair (ACS Nano, doi: 10.1021/acsnano.3c11030). The laser-writing technique prints the structures with subwavelength resolution on a platform roughly 125 μm wide.

Using the new method, the scientific team created two working devices: a refractive index sensor and a polarization beam splitter. The researchers suggest that the fabrication technique could find many applications in sensing, photonic circuitry and microfluidics.

Cooler glass curing

Previous efforts to fabricate fiber-tip devices with 3D direct laser writing have run into material-related snags. An earlier generation of polymer-based fiber-tip sensors degraded and failed upon exposure to either organic solvents or temperatures about 300°C. Other scientists have tried to fabricate glass fiber-tip structures at temperatures above 650°C, which degraded the temperature-sensitive fiber coatings and jackets.

The team from Kristinn Gylfason’s lab at KTH Royal Institute of Technology found a better way to cure the glass being deposited: femtosecond laser pulses at a wavelength of 1040 nm. Lead study author Lee-Lun Lai and his colleagues placed the end of a standard single-mode optical fiber in a holder to keep it steady during the fabrication process. On this tiny flat surface, the team deposited a mixture of hydrogen silsesquioxane (HSQ) and toluene. Once the solvent was evaporated, leaving the glass material behind, the infrared laser (with a pulse width of less than 400 fs) selectively cured the HSQ via nonlinear absorption, with software to controlling the laser’s movement to an accuracy of 0.3 μm. Then, a developer solution containing potassium hydroxide washed away the uncured HSQ, leaving the desired structure on the fiber tip.

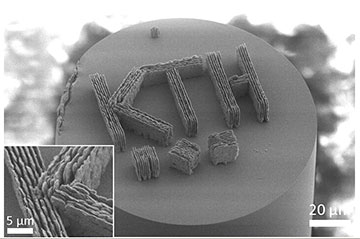

Microscopic image of a printed glass demonstration structure on the tip of optical fiber. [Image: David Callahan]

One variant of the new method, “uniform mode,” allowed the team to print solid micro-optical components such as a smooth-surfaced glass cube, which gave the researchers the basis for measuring the refractive index of the deposited glass. With the other variant, “nanograting mode,” they printed out tiny periodic gratings; the team could vary the periodicity by changing the laser wavelength or doping the HSQ solution to change the structures’ refractive index.

Tiny, but useful, devices

The fiber-tip sensor built in uniform mode by Lai and his colleagues consisted of a glass plate measuring 10 × 10 × 3.5 μm, with tiny posts holding the plate 8.5 μm above the end of the optical fiber. The whole thing worked as an open Fabry-Pérot interferometer under broadband illumination.

The polarization beam splitter, created in nanograting mode, contained two blocks of subwavelength gratings orthogonal to each other. A near-infrared laser diode and camera completed the proof-of-concept testing setup. Such a splitter could be used within hybrid integrated quantum photonic circuits, according to the authors.