The Columbia University lab of Alex Gaeta has demonstrated a method for “unzipping” atomically sharp features in 2D hexagonal boron nitride, using mid-IR light from a tabletop laser setup. [Image: Gaeta Lab / Columbia Engineering]

The ability to engrave or pattern nanostructures in a variety of materials has opened doors across electronics and photonics, enabling new plasmonic devices and metamaterials. But the techniques for creating such nanopatterns—electron-beam lithography, chemical etching and femtosecond laser writing—aren’t exactly the stuff of the weekend hobbyist. Instead, these approaches typically require multistep processing in expensive cleanroom settings. And they can damage samples and leave residue or debris in their wake.

Now, the lab of Alexander Gaeta at Columbia University, USA, has devised a way to create at least one type of nanopatterning—straight, atomically sharp cuts in a 2D material—using only a mid-IR laser in free space (Sci. Adv., doi: 10.1126/sciadv.adi3653). To pull off this neat trick, the team carefully tuned the laser to excite resonant vibrational phonons in the material into a frenzy, causing a straight, atomically precise crack to form and propagate across the material. The result? Sharp, nanoscale features; no cleanroom needed.

The team calls the technique “unzipping.” And one striking aspect of it is that the nanometer-scale sharpness of the cracks it produces is orders of magnitude smaller than the mid-IR wavelength of the driving laser. “Usually, you need a shorter wavelength to make a smaller pattern,” Cecilia Chen, the Columbia grad student who led the work, said in a press release describing it. “Here, we can create very sharp nanostructures using very long wavelengths. It’s a paradoxical phenomenon.”

Zeroing in on hBN

The layered 2D material that Chen and the team selected as a testbed for the unzipping technique was hexagonal boron nitride (hBN). This material, with a long pedigree as a lubricant and a cosmetics additive, has recently drawn interest as a promising photonic and optoelectronic material—both as a substrate for another 2D material, graphene, and in a number of nonlinear-optics applications.

One striking aspect of the technique is that the nanometer-scale sharpness of the cracks it produces is orders of magnitude smaller than the mid-IR wavelength of the driving laser.

Some of hBN’s potential charms relate to its crystal structure’s strong vibrational (phonon) resonance at a free-space optical wavelength of 7.3 µm, a zone accessible to tabletop mid-IR lasers. Indeed, in work published late last year, Gaeta’s team showed that tickling high-quality hBN flakes with a laser tuned to that wavelength could induce and amplify optical nonlinearities such as four-wave mixing and third-harmonic generation in the material. In that study, the aim was to enhance the intact crystal’s nonlinear properties, so the researchers purposely kept the mid-IR laser intensity below 50 TW/cm2, the estimated damage threshold for hBN.

Driving things harder

In the new study led by Chen, the team wanted to find out if the same mid-IR resonances could be used to actually modify the hBN crystals. To do so, they started with a similar experimental setup, and then drove the laser harder to pass the damage threshold.

Specifically, the team chained together a Ti:sapphire mode-locked oscillator, a chirped-pulse amplifier, an optical parametric amplifier and a difference-frequency generation module into a tabletop system to create a stream of 120-fs, 7.3-µm-wavelength pulses at a 1 kHz repetition rate. The pulse beam was reflected and routed through a 40× microscope objective, and focused down to an intensity ranging from 50 to 65 TW/cm2 onto a sample of ultra-high-purity hBN. An adjustable electronic shutter in the beam path let the team further control the number pulses reaching the sample.

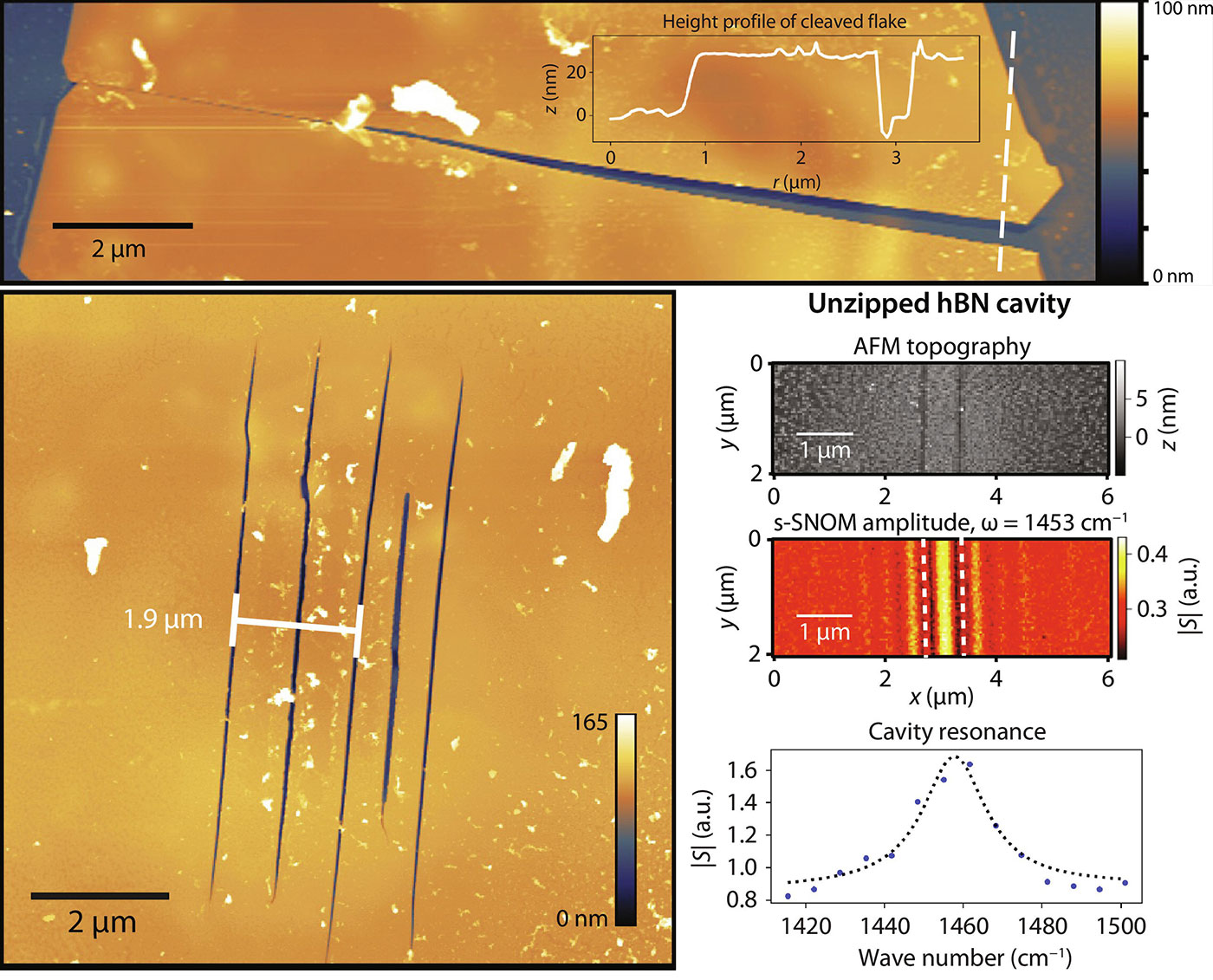

AFM images show examples of the nanoscale features enabled by the mid-IR unzipping technique, including long linear cracks (top), a quasi-periodic grating structure (bottom left), and a two-crack Fabry-Pérot cavity for confining and amplifying phonon polaritons (bottom right) [Image: C.Y. Chen et al., Sci. Adv., doi: 10.1126/sciadv.adi3653 (2024); CC BY-NC 4.0]

The team found that the laser treatment led to the seeding of a crack in the laser spot—perhaps as a result of an internal defect in the hBN crystal—that in turn triggered rapid, “largely unidirectional” crack-tip propagation through the crystal. The researchers were able to watch the process unfold in real time through the microscope, and estimated the speed of crack propagation at 100 µm/s.

Atomic-force microscopy and atomic-scale lateral force microscopy confirmed that the resulting features were atomically sharp. The team also found that the technique’s efficiency hinged not only on careful tuning of the laser wavelength, but also (not surprisingly) on lining up the laser’s polarization precisely to take advantage of the crystal’s symmetry system.

Escape from the cleanroom?

Using a mid-IR tabletop laser to create nanometer-scale features is unquestionably a cool accomplishment. But what might it be useful for?

At the very least, Chen and her colleagues believe it could offer a new, cleanroom-free method for carving up hBN for use in heterostructures. Indeed, the researchers suggest that, by irradiating adjacent regions with laser light of different polarizations, more complex, custom flake shapes could be enabled for applications such as semiconductor mask patterning. The team also showed that the technique could be used to create quasi-periodic grating structures in hBN.

Perhaps more intriguing are some potential applications in creating phonon polaritons—vibrational quasiparticles that arise from the coupling of photons and optical phonons. These quasiparticle modes are promising in a variety of areas including below-diffraction-limit imaging, some quantum applications and the miniaturization of optical devices. The team’s experiments suggest that infrared illumination can excite these useful quasiparticles much more efficiently at the ultrasharp boundaries created by the unzipping method than at the natural edges of a typical hBN flake. The team was even able, in one sample, to create a Fabry-Pérot cavity for confining and amplifying such phonon polaritons by unzipping two lines in parallel.

Cecilia Chen, the grad student who led the research. [Image: Columbia Engineering]

There is still plenty of room to improve the technique, Chen noted in the press release accompanying the research. In particular, the unzipping process is rather finicky, requiring a carefully tuned laser and precise orientation for optimal results. It is also, right now, specific to hBN, with that material’s 7.3-µm-wavelength resonance.

Different lasers, however, could allow the process to be exported to other materials. On that head, the study authors note that silicon carbide (SiC)—an increasingly important substance both for quantum applications and the electrification of society, but one that’s also difficult to process—is, like hBN, a polar crystal with IR-active optical phonons, with a resonance wavelength of around 10 µm. Perhaps, with the right laser, unzipping could become part of the SiC-processing toolkit, too.